A guide to ISO 9001 Supplier Audit

| Section | Summary |

|---|---|

| Introduction to ISO 9001 Supplier Audit | Introduction to the concept of supplier audit under ISO 9001, its significance, and impact on quality management. |

| The Role of ISO 9001 in Supplier Audits | Explanation of how ISO 9001 enhances supplier audits, setting standards for supplier evaluation and continual improvement. |

| Setting Objectives for ISO 9001 Supplier Audit | Guide to establishing clear, measurable objectives that align with the organization’s quality goals for the audit. |

| ISO 9001 Supplier Audit Planning | Overview of the planning process for the audit, including assembling the audit team, determining the scope, and preparing checklists. |

| Executing the ISO 9001 Supplier Audit | Detailed procedure on how to conduct the audit, from initial meetings, data collection, to identifying non-conformities and improvement opportunities. |

| Post-Audit Activities | Exploration of post-audit tasks, including the preparation of the audit report, evaluation of corrective actions, and conducting follow-up audits. |

| Challenges and Solutions in ISO 9001 Supplier Audit | Discussion of potential challenges faced during supplier audits and the effective strategies to overcome them. |

ISO 9001:2015, a flagship standard of the International Organization for Standardization, provides a framework for Quality Management Systems (QMS) and is rooted in several quality management principles, including a robust customer focus, management leadership, a process approach, and a continual improvement ethos. A well-implemented ISO 9001 system is indicative of a business’s commitment to quality, reliability, and customer satisfaction.

A supplier audit, as it relates to ISO 9001, is an in-depth review of a supplier’s procedures, policies, and processes to ascertain if they meet the requirements set out in this standard. The rationale is to gauge a supplier’s ability to deliver goods or services that consistently meet the organization’s needs and expectations, alongside relevant regulatory and statutory requirements. They are a key facet of supply chain quality management, underlining an organization’s desire for efficiency and reliability in their suppliers.

In an ever-more interconnected global business landscape, the performance of your suppliers has a far-reaching impact on your organization’s success. Consequently, a diligent approach to ISO 9001 supplier audits is no longer an optional exercise but a critical necessity.

II. The Role of ISO 9001 in Supplier Audits

ISO 9001’s impact is far-reaching and deeply integrated within various business operations. Its role in supplier audits is particularly significant, providing a comprehensive framework and structured approach to assess and enhance supplier performance.

A. Unpacking ISO 9001: A Refresher

ISO 9001, in essence, is an international standard that defines the criteria for a Quality Management System (QMS). It applies to any organization, regardless of its size or the nature of its business. ISO 9001 is based on seven quality management principles: customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management.

Each of these principles contributes to a systematic approach to identifying risks, improving processes, and ensuring customer satisfaction. Within the context of supplier audits, these principles become tangible tools, providing a roadmap to supplier performance assessment and improvement.

B. ISO 9001 and Supplier Management

ISO 9001:2015, the latest iteration of the standard, emphasizes risk-based thinking and supplier management. Clause 8.4 – Control of Externally Provided Processes, Products, and Services directly addresses the expectations concerning suppliers. It requires an organization to ensure that externally provided processes, products, and services conform to specified requirements. It also urges organizations to apply criteria for the evaluation, selection, monitoring of performance, and re-evaluation of external providers, thereby placing supplier audits firmly within the ISO 9001 purview.

C. ISO 9001 Supplier Audit: A Mechanism for Risk Management

Risk management is a core aspect of the ISO 9001 standard. By integrating risk-based thinking into all its processes, it encourages organizations to proactively identify potential process lapses or vulnerabilities that could compromise quality. Supplier audits play an instrumental role in this process by identifying and mitigating risks within the supply chain. Through an ISO 9001 supplier audit, organizations can scrutinize suppliers’ risk management practices, disaster recovery plans, and overall reliability.

D. Driving Continual Improvement with ISO 9001 Supplier Audits

One of the main tenets of ISO 9001 is continual improvement. The standard pushes organizations to consistently seek ways to optimize their processes, products, or services. When applied to supplier audits, this principle propels organizations to utilize audit findings not just for corrective action, but also as a basis for driving supplier performance enhancement and fostering more robust, mutually beneficial supplier relationships.

E. Ensuring Regulatory Compliance

ISO 9001 supplier audits help organizations to verify that their suppliers adhere to all relevant legal and regulatory requirements. These may vary depending on the nature of the products or services supplied, geographical factors, industry specifics, and other considerations. By adhering to the ISO 9001 standard during a supplier audit, organizations can systematically ensure regulatory compliance across the supply chain.

As we delve deeper into the ISO 9001 supplier audit process in the following sections, these theoretical concepts will take on a more practical hue. The goal is to provide a step-by-step roadmap that can be customized and implemented by quality engineers, managers, and other stakeholders to ensure robust, compliant, and efficient supplier operations.

III. Setting Objectives for ISO 9001 Supplier Audit

In the journey of conducting a robust ISO 9001 supplier audit, a crucial first step is the setting of clear, measurable, and relevant audit objectives. Articulated objectives provide a sense of direction and establish the scope of the audit, guiding the audit team’s efforts and driving the audit’s overall success.

A. Understanding the Importance of Defining Audit Objectives

Effective supplier audits do not occur in a vacuum. They are driven by well-constructed objectives that align with an organization’s overarching quality management goals. These objectives serve as a compass, directing the audit’s course and providing benchmarks against which audit findings can be measured. Clear objectives also enable effective communication to the supplier about what the audit will entail and what aspects of their operations will be under scrutiny.

B. Identifying Key Factors Influencing Audit Objectives

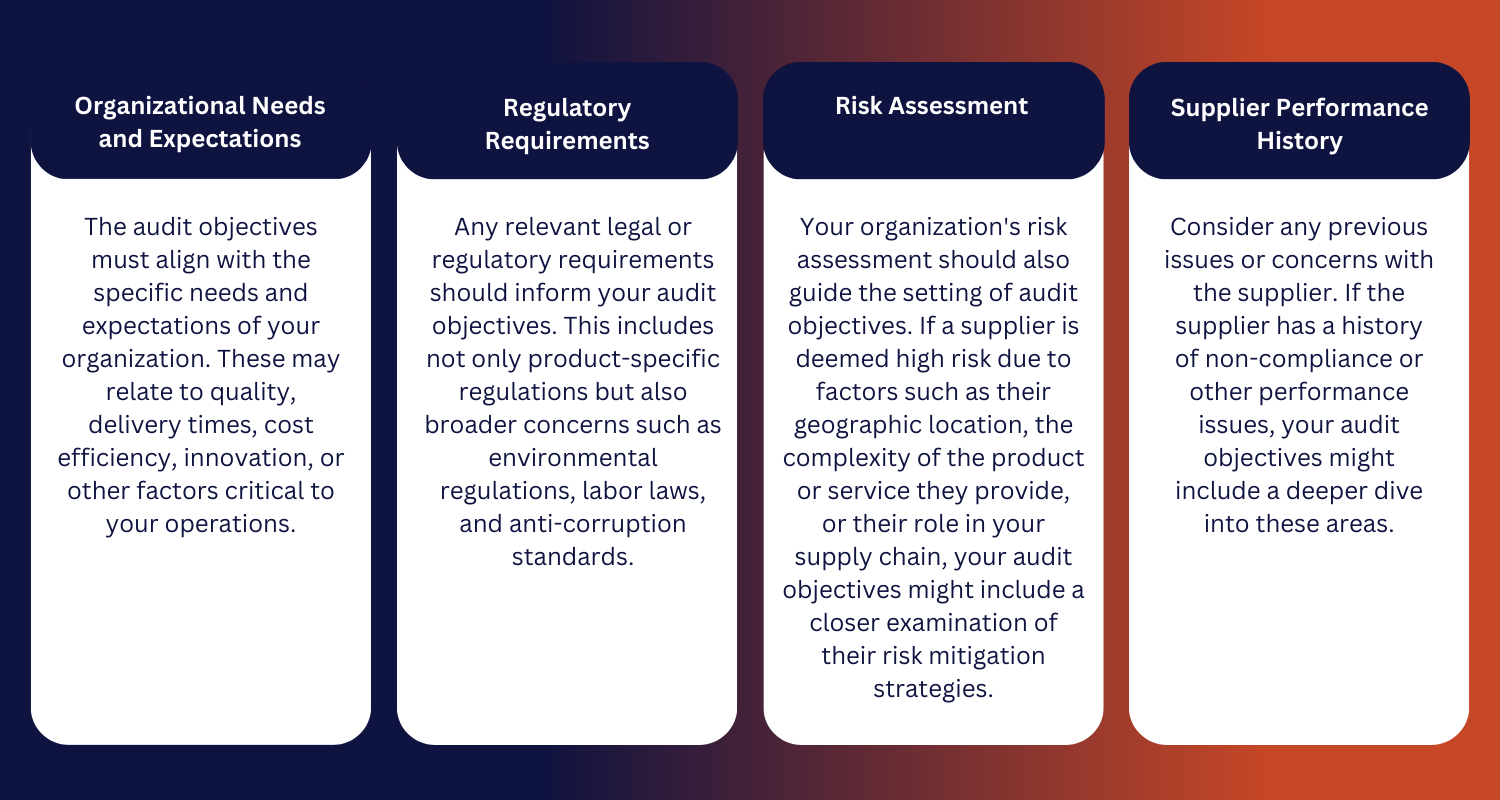

When defining objectives for a supplier audit, several key factors should be taken into account.

C. Constructing Effective Audit Objectives

Having considered the influencing factors, the task now is to translate these into effective audit objectives. Good audit objectives should be SMART: Specific, Measurable, Achievable, Relevant, and Time-bound. For example, rather than an objective like “Improve product quality,” a SMART objective might be “Decrease the percentage of defective components received from the supplier by 20% over the next six months.”

D. Creating an Audit Checklist

Once you have your objectives, you can create an audit checklist, a critical tool for ensuring a thorough and focused audit. The checklist should be tailored to your audit objectives and used as a guide during the audit to ensure no area is overlooked. It can include points such as verifying certifications, inspecting physical facilities, reviewing process documentation, or interviewing staff.

Setting well-defined objectives lays a solid foundation for an effective ISO 9001 supplier audit. It fosters an organized and systematic approach to supplier evaluation, ensuring that the process delivers valuable insights aligned with the organization’s quality management goals. As we continue to explore the supplier audit process, the importance of these objectives and their role in shaping a successful audit will become increasingly clear.

IV. ISO 9001 Supplier Audit Planning

The value of meticulous planning cannot be overstated when embarking on an ISO 9001 supplier audit. The planning phase, informed by the clearly set audit objectives, is where the course is charted, ensuring an effective, efficient, and comprehensive audit. This section delves into the intricate facets of audit planning.

A. Elements of an Effective Audit Plan

An audit plan should act as the blueprint for the entire audit process, encompassing all the vital steps, key personnel involved, timelines, and the logistics of the audit. The plan should also detail the methodologies that will be used during the audit, such as on-site inspections, personnel interviews, or document reviews.

To ensure the plan’s thoroughness, it must include:

-

- Scope of the Audit: Clearly define what the audit will cover, including departments, processes, or products based on the audit objectives.

- Audit Criteria: Establish the benchmarks or standards against which the supplier will be evaluated. This will typically be the ISO 9001 standard but may also include other industry-specific standards or regulatory requirements.

- Audit Methodology: Identify the techniques and procedures that will be used during the audit, such as document reviews, interviews, or observations of working practices.

- Audit Schedule: Create a timeline for the audit, including the dates and times for specific audit activities and the expected duration of the audit.

- Audit Team: Detail the team members who will be conducting the audit and their respective roles. Each member’s area of expertise should be considered when assigning responsibilities.

B. Selection and Role of the Audit Team

The audit team’s selection is a critical component of the planning process. The team should comprise individuals with a deep understanding of the ISO 9001 standard and a strong knowledge of the products or services provided by the supplier. Team members should also have strong interpersonal skills and an ability to stay objective and impartial throughout the audit.

The team should have a designated lead auditor, who will be responsible for coordinating the audit, liaising with the supplier, and compiling the audit report. The lead auditor typically has advanced training and significant experience in conducting audits.

C. Supplier Communication

Communication with the supplier is another critical aspect of the audit planning process. The supplier should be notified of the planned audit well in advance. The notification should include the audit’s purpose, the planned dates, the scope and criteria of the audit, and who will be involved.

It’s also beneficial to request any necessary documentation from the supplier in advance, such as quality manuals, process diagrams, or previous audit reports. This allows the audit team to familiarize themselves with the supplier’s operations before the audit and can help identify any potential issues to be addressed during the audit.

By meticulously planning the supplier audit, organizations can ensure a smooth and effective process that generates valuable insights into the supplier’s operations and performance. As we move into the execution phase of the audit in the next section, the benefits of thorough planning will become even more evident.

V. Executing the ISO 9001 Supplier Audit

With an audit plan meticulously crafted and primed for deployment, we now venture into the heart of the ISO 9001 supplier audit: its execution. This stage is where planning meets action, as the audit team delves into the supplier’s operations to gather data, validate compliance, and identify potential areas for improvement.

A. Opening Meeting: Setting the Stage

The execution phase of an ISO 9001 supplier audit begins with an opening meeting. The lead auditor should present the audit plan to the supplier’s representatives, outlining the scope, criteria, and schedule of the audit. This meeting is also the time to address any concerns or queries the supplier may have and to emphasize the cooperative and constructive nature of the audit process.

B. Audit Activities: Data Collection and Validation

The crux of the audit process is the collection and validation of data related to the supplier’s processes, products, and services. This typically involves a range of activities:

-

- Document Review: The audit team should examine the supplier’s quality documentation, such as their Quality Management System (QMS) manual, process documents, and records, to verify their compliance with ISO 9001 requirements.

- Observation of Operations: By observing the supplier’s activities in real-time, the auditors can gain insights into actual practices, workplace culture, and the effective implementation of documented procedures.

- Interviews: Talking directly with the supplier’s personnel can reveal valuable information about their understanding of and commitment to quality practices. It can also help the auditors validate the consistency between the documented procedures and the actual practices.

C. Identifying Non-Conformities and Opportunities for Improvement

As data is collected and analyzed, the audit team should identify any non-conformities – instances where the supplier’s practices do not meet the ISO 9001 standard or the organization’s specified requirements. Non-conformities should be documented in detail, including the nature of the non-conformity, the evidence on which it is based, and its potential impact.

Simultaneously, the team should identify opportunities for improvement, even in areas where the supplier is compliant. These opportunities, while not mandatory for the supplier to address, can help enhance efficiency, reduce risk, and improve overall performance.

D. Closing Meeting: Initial Feedback and Next Steps

The execution phase of the audit concludes with a closing meeting. The audit team should present their initial findings, including any non-conformities and opportunities for improvement. This is also the time to discuss the next steps in the audit process, including the timeline for the supplier to respond to the findings and the expected date for the final audit report.

Executing the ISO 9001 supplier audit is a complex and critical process, requiring a balanced blend of technical acumen, investigative rigor, and diplomatic tact. As we transition into the post-audit phase in the next section, we will see how the data gathered during the execution phase is synthesized and utilized to drive improvements.

VI. Post-Audit Activities

The completion of the execution phase of the ISO 9001 supplier audit does not signal the end of the audit journey. The post-audit phase, as significant as the other stages, is where findings are documented, responses are evaluated, and continuous improvement initiatives are implemented. This section unpacks the critical components of post-audit activities.

A. Compilation and Distribution of Audit Report

At the conclusion of the audit, the lead auditor is tasked with compiling a comprehensive audit report. This report should document in detail the audit’s findings, including any non-conformities or opportunities for improvement that were identified. It should also provide a summary of the audit process, noting areas covered, methodologies used, and any limitations encountered.

Once the report is finalized, it should be distributed to relevant stakeholders. This typically includes the organization’s management, the audit team, and the supplier. It’s also valuable to share the report with other departments in your organization, such as purchasing or engineering, as the findings can provide insights to inform their decisions and actions.

B. Supplier’s Response and Corrective Actions

Upon receiving the audit report, the supplier is expected to respond to the identified non-conformities. They should provide a root cause analysis for each non-conformity and outline their proposed corrective actions. These actions should be specific, measurable, and time-bound, aimed at eliminating the cause of the non-conformities to prevent recurrence.

The audit team should review the supplier’s responses to ensure that they adequately address the issues raised. If necessary, the team might request additional information or clarification from the supplier.

C. Follow-up Audits and Continuous Improvement

After the supplier has implemented their corrective actions, a follow-up audit may be conducted to verify the effectiveness of these actions. This helps to ensure that the non-conformities have been resolved and are not likely to recur.

But the journey doesn’t end there. ISO 9001 supplier audits are part of a continuous improvement cycle. Learnings from one audit should feed into the planning of the next, allowing your organization to continuously enhance its supplier evaluation processes and drive ongoing improvements in supplier performance.

In summary, the post-audit activities are an essential step in the ISO 9001 supplier audit process. They ensure that the insights gathered during the audit are put to practical use, leading to the ongoing enhancement of supplier performance and, ultimately, the delivery of high-quality products and services to your customers. As we have seen throughout this exploration of the ISO 9001 supplier audit process, every step plays a vital role in achieving these outcomes.

VII. Challenges and Solutions in ISO 9001 Supplier Audit

Like any complex process, ISO 9001 supplier audits present unique challenges that may, at times, seem to impede the smooth execution of the audit. But these hurdles should not deter your pursuit of a comprehensive supplier evaluation. Instead, each challenge presents an opportunity to refine your auditing approach and to ensure a more effective and efficient audit process. Here, we discuss common challenges that organizations face and provide practical solutions to address them.

A. Challenge: Supplier Resistance or Lack of Cooperation

Occasionally, suppliers may resist the audit process or exhibit a lack of cooperation, viewing the audit as an intrusion or an unnecessary burden. This resistance can pose a significant hurdle to executing a comprehensive audit.

Solution: Open Communication and Collaboration

The key to overcoming supplier resistance is fostering an atmosphere of open communication and collaboration. Frame the audit as a mutually beneficial process aimed at continuous improvement, rather than a punitive or fault-finding exercise. Ensure the supplier understands the audit’s objectives and how it can help enhance their processes and strengthen the partnership.

B. Challenge: Resource Constraints

Supplier audits require significant resources in terms of personnel, time, and costs. Resource constraints can therefore pose a significant challenge, particularly for smaller organizations or for those with a large number of suppliers.

Solution: Risk-Based Audit Planning

To overcome this challenge, organizations can employ a risk-based approach to audit planning. This involves identifying high-risk suppliers or areas based on factors such as previous audit results, supplier performance, or the criticality of the supplier’s products or services. By focusing audit efforts on these high-risk areas, organizations can maximize the impact of their audits while optimizing the use of resources.

C. Challenge: Inconsistent Audit Methodologies

Different auditors or audit teams may employ varying methodologies or interpret the ISO 9001 standard differently, leading to inconsistencies in audit results.

Solution: Standardized Training and Audit Procedures

Standardized auditor training and well-defined audit procedures can help ensure a consistent approach to supplier audits. Regularly updating and refining these procedures based on learnings from previous audits can also enhance the effectiveness and consistency of audits.

D. Challenge: Managing and Analyzing ISO 9001 Supplier Audit Data

The wealth of data generated from supplier audits can be overwhelming, making it difficult to manage and analyze the data effectively.

Solution: Effective Data Management Systems

Utilizing effective data management systems, including quality management software, can help streamline the collection, storage, and analysis of audit data. These systems can facilitate trend analysis, identify recurring issues, and provide insights to inform future audit planning.

In conclusion, while the ISO 9001 supplier audit process can present challenges, it’s important to remember that these hurdles are not insurmountable. With a proactive approach and a focus on continuous improvement, these challenges can be transformed into stepping stones that propel your supplier audit process to greater heights.